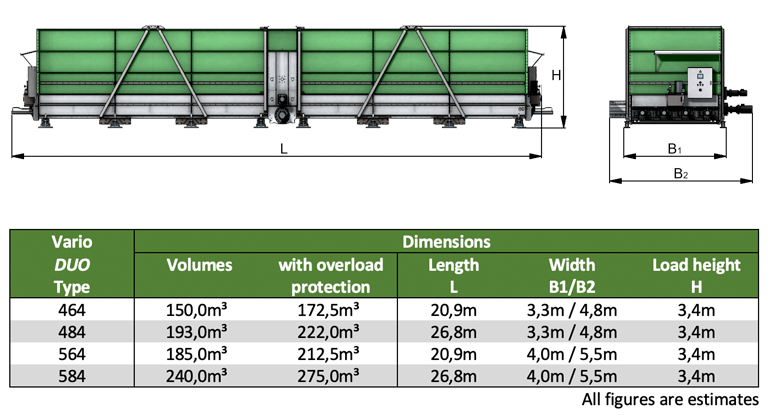

Vario DUO Dosage Container

Many years of experience have taught us that every plant has its own individual challenges due to such things as local conditions, substrate type, the size of the plant, etc.

If our Vario dosage container is too small to meet your needs, the Vario DUO dosage container, whose modular design permits us to make available in the size range 150m³–275m³, may offer the perfect alternative.

HYDRAULIC UNIT

An electrically powered hydraulic unit is used to drive the Vario push components.

CONTROL

The standard system comes equipped with a Siemens S7 that permits autonomous control. It can also be integrated into new or existing control systems.

STORAGE CONTAINER

The container is impervious to fluids. Its modular construction allows it to be expanded later.

DISSOLVING AUGER / SCREW

The dissolving auger and screw permit even, unobstructed dosing, even with substrates that are cumbersome to transport.

TRANSMISSION & MOTORS

We use planetary gear technology, which provides a high degree of efficiency and is highly resistant to wear and tear.

DISCHARGE SCEW CONVEYOR

The position of the integrated discharge screw conveyor allows for the even delivery of the substrate.

WEIGHING SYSTEM (OPTIONAL)

The optional inclusion of a weighing system allows the user to determine the filling weight of the storage container. In combination with our control equipment, this enables precision dosing of the substrate.

VARIO CONVEYOR COMPONENTS

Vario’s conveyor rails are made of stainless steel and plastic. The outstanding efficiency and stability of this technology is unrivalled in this entire branch of industry.

CYLINDER OPERATION

The stainless steel piston rods in the hydraulic cylinders are equipped with a dual seal, which prevents the substrate from mixing with hydraulic oil.

One of its special features is our Vario conveyor rails. Their alternating conveyor mechanism allows for the steady, even discharge of materials. When the conveyor elements are moving forward, the push components unfold to powerfully drive the materials in the output direction. When the rails are moving backwards, the push components lie flat and slide through the material with very little resistance, allowing very little material to be pulled backwards.

One of its special features is our Vario conveyor rails. Their alternating conveyor mechanism allows for the steady, even discharge of materials. When the conveyor elements are moving forward, the push components unfold to powerfully drive the materials in the output direction. When the rails are moving backwards, the push components lie flat and slide through the material with very little resistance, allowing very little material to be pulled backwards.

In its standard configuration, the Vario dosage container can output 40% grass and manure at up to 20 m³/h, depending on the substrate. You can find further output performance statistics, as well as grass and manure packs, under Equipment and Accessories.

Vario equipment can be integrated with all the usual subsequent equipment.

We can deliver and manage the following systems, together with all their accompanying components, in their entirety.

- Mixing pump (slurry system)

- Feed pump

- Crushing equipment (mill)

- Screw technology

Standard Sizes

Equipment and Accessories

Overcharge Protection

Overcharge protection is available for all Vario dosage containers. In the standard version, it is made of powder-coated steel plating.

Overcharge protection is available for all Vario dosage containers. In the standard version, it is made of powder-coated steel plating.

Overcharge protection increases the volume by around 15%. It prevents the substrate from spilling out over the edge of the container, which also keeps the area around the container significantly cleaner.

(Overcharge protection cannot be installed in combination with a hydraulic lid.)

Hydraulic Lid (Truck/Lorry Loading)

To minimise emissions and weather damage, the Vario dosage container can be fitted with a hydraulic lid, operated using a wireless remote control.

For example, if you are planning to load your Vario dosage system using a truck or lorry, we can offer you a variety of customised solutions.

(The hydraulic lid cannot be fitted in combination with overcharge protection.)

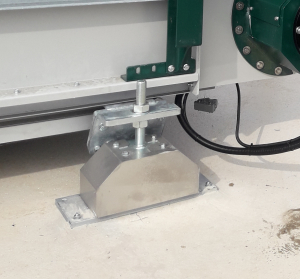

Weighing System incl. Large Screen Display

Our weighing system incorporates a clearly legible large screen display to register how full the Vario dosage container is. In combination with our Vario control system, this allows for precision dosage of the substrate.

Our weighing system incorporates a clearly legible large screen display to register how full the Vario dosage container is. In combination with our Vario control system, this allows for precision dosage of the substrate.

Also available:

-A selection of 6 components, incl. wireless remote control

-Covers for weighing feet

Grass and Manure Packs (for heavy and long-fibre substrates)

In its standard configuration, the Vario dosage container can reliably handle up to 40% grass and manure. If higher proportions need to be processed, the percentage of grass and manure can be increased to 70% and 100% in two steps. These features can also be added to the Vario equipment at a later stage.

Raising Output Performance

The standard configuration can deliver up to 20 m³/h, depending on the substrate.

Output performance can be increased to up to 100 m³/h.

Partially or Fully Stainless Steel and Steel Models

The standard partially stainless steel model:

All the inner parts of the floor and the container’s first C-profile ring, which come into contact with the substrate, are made of stainless steel and plastic, as are all parts of the conveyor equipment and the screws. All other parts are made of powder-coated steel.

The fully stainless steel model:

In the fully stainless steel model, the entire inner container, i.e. all parts that come into contact with the substrate, is made of stainless steel and plastic, as are all parts of the conveyor equipment and the screws.

The steel model (only for non-corrosive substrates!)

In the steel model, the entire inner container, i.e. all parts that come into contact with the substrate, is made of steel, as are all parts of the conveyor equipment and the screws.

Special Paintwork

The Vario dosage container is available in other colours, on request.

Standard Colours:

- C profile (steel): moss green (RAL 6005).

- C profile (stainless steel): aluminium white (RAL 9006).

- Substructure and side supports: zinc plated

- Motors, transmission crossbeams, cylinders etc.: deep black (RAL 9005)

Special Electrical Features

- Remote access module

- Load-dependent control

- Integration with ProfiNET / Profibus DP

- Operating indicator light