Dosiersystem TT

Our TT dosage system offers you the ideal feeding system, specially developed for small plants. It is available in 3 m³–13 m³ sizes.

CONTROL

The standard system comes equipped with a Siemens S7 that permits autonomous control. It can also be integrated into a new or existing control system.

STORAGE CONTAINERS

The container is impervious to fluids. Its modular construction allows it to be expanded later.

DISSOLVING SCREW

The dissolving screw permits even, unobstructed dosing, even with substrates that are cumbersome to transport.

DISCHARGE SCEW CONVEYOR

The position of the integrated discharge screw conveyor allows for even delivery of the medium.

TRANSMISSION & MOTORS

We use planetary gear technology, which provides a high degree of efficiency and is resistant to wear and tear.

The TT dosage system incorporates a discharge screw conveyor and an opening screw, allowing for reliable dosage. Its resistance to wear and tear and low electricity usage make it a good alternative to other solid material feeding systems in smaller plants.

In its standard configuration, the dosage system can produce an output of up to 20 m³/h, depending on the substrate. Further performance outputs can be customised to meet your individual needs.

The TT dosage system can be integrated with all the usual subsequent equipment. We can deliver and manage the following systems, together with all their accompanying components, in their entirety.

- Pumping equipment

- Screw technology

Standard Sizes

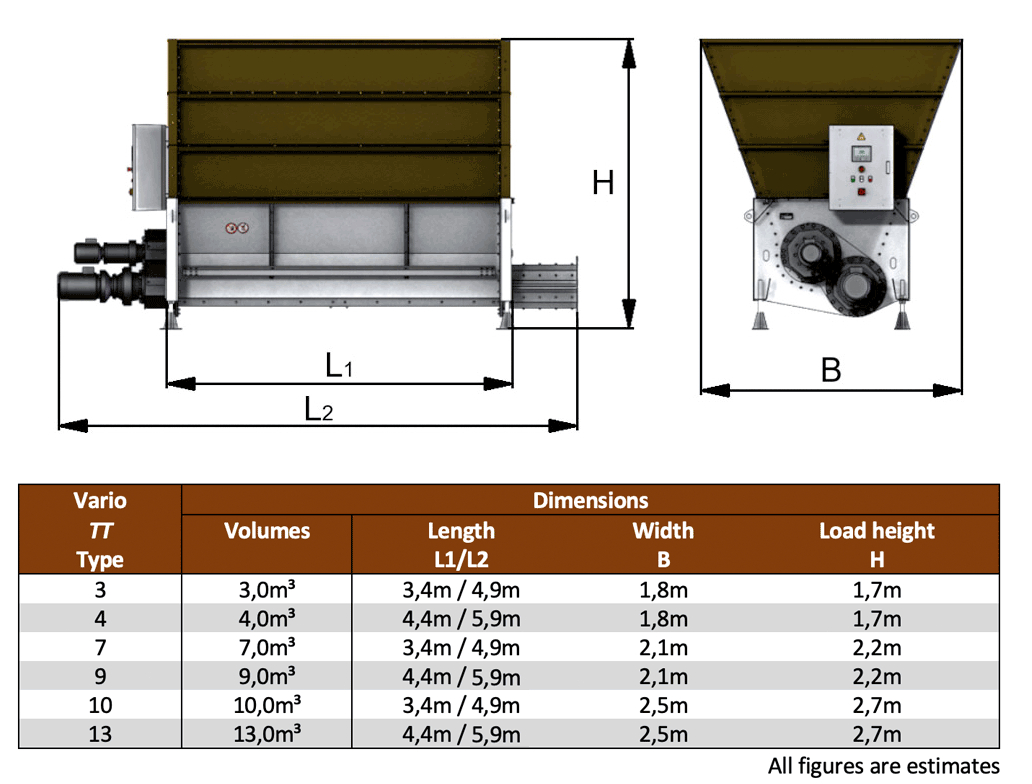

Standard Sizes 3m³ -13m³

Equipment and Accessories

Fully and Partially Stainless Steel Models

The standard partially stainless steel model:

The lower screw trough and all surrounding parts that come into contact with the medium are made of stainless steel and plastic, as are all parts of the conveyor equipment and the screws. All other parts are made of powder-coated steel.

The fully stainless steel model:

In the fully stainless steel model, the entire inner part of the dosage system, that is, all the parts that come into contact with the medium, is made of stainless steel and plastic, as are all parts of the conveyor equipment and the screws.

Special Paintwork

The Vario dosage container is available in other colours, on request.

The Vario dosage container is available in other colours, on request.

Standard Colours:

- C profile (steel): moss green (RAL 6005).

- C profile (stainless steel): aluminium white (RAL 9006).

- Substructure and side supports: zinc plated

- Motors, transmission crossbeams, cylinders etc.: deep black (RAL 9005)

Filling Status Monitoring

To allow you to monitor filling status, we offer the appropriate system for each medium. Used in combination with our Vario control system, this ensures precision dosage of the medium.

- Radar sensors

- Laser sensors

- Rotary position monitors

- Weighing systems

Special Electrical Equipment

- Wireless remote control unit

- Load-dependent control

- Integration in ProfiNET / ProfiBUS DP

- Operating indicator lamp

- Tricolour operating indicator column

- Load break switch